Learn More about Strain Gauges and Strain Meters

When installed, Strain gauges and strain meters provide ongoing monitoring of strain at key points in the structure, providing the information essential to maintaining balanced structural integrity. Strain gauges and strain meters can be welded to or embedded in various structures, depending on the product and specific application. Rebars embedded in concrete, cable bolts, and steel members are just a few of the supporting components that must be monitored in order to protect the integrity of the overall structure.

RST’s Vibrating Wire Rebar Strain Meter, also called sister bar, is designed to measure strain on rebar embedded in concrete and is affixed to the rebar cage itself. These gauges are commonly used in concrete piles, diaphragm walls, and concrete foundation slabs.

The Vibrating Wire Strain Gauge is similar in function and is available in three different models suited to different modes of installation—two for use on steel structures, and one designed to be embedded in concrete.

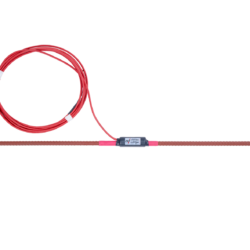

For 7-wire strand tension monitoring, RST offers the TENSMEG—a strain gauge specifically designed to measure load and strain in wire strands, rock anchors, and cable bolts.

Ongoing monitoring and recording of structural strains is made possible by the QB120 Resistance Strain Gauge Readout, RST VW2106 Vibrating Wire Readout or DT series Data Loggers.