Posts by Category

Recent Posts

- Leveraging ShapeArray for wireless automated remote deformation monitoring

- United under Orica Digital Solutions, Terra Insights and GroundProbe merge geotechnical technologies and capabilities

- Terra Insights joins Orica, expanding digital solutions platform

- Wide-area linear infrastructure monitoring with InSAR and Instrumentation: Your questions answered

- How to improve blasting practices in mining operations with vibration and air pressure monitoring: Your questions answered

- ShapeArray Fundamentals in 2023: Your questions answered

For too long interferometric synthetic aperture radar (InSAR) and geotechnical instrumentation have been regarded as separate or even rival monitoring technologies. These technologies are not mutually exclusive but are best understood as complementary technologies that create actionable data for risk mitigation.

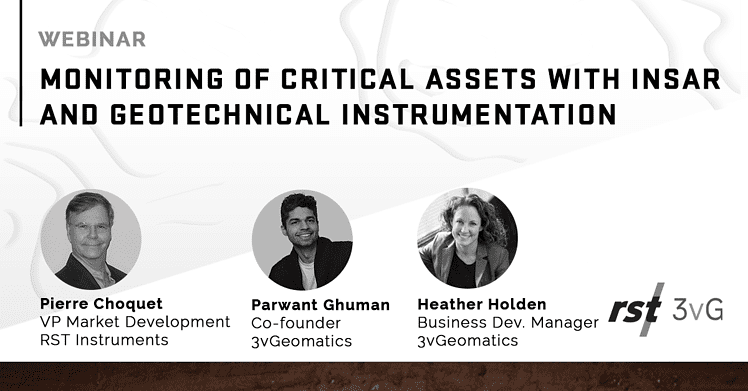

3vGeomatics‘ Parwant Ghuman and Heather Holden, along with RST Instruments’ Pierre Choquet presented a live webinar that explored the benefits of a holistic approach to critical asset monitoring using geotechnical instrumentation combined with InSAR.

Key takeaways:

- InSAR can provide early warning of risk

- InSAR and ground instruments complement each other

- InSAR together with ground instruments help keep your risk models up-to-date

We’ve compiled registrants’ questions and answers to help learn how a monitoring strategy that combines InSAR and in-ground instrumentation can mitigate risk.

Questions and answers

Heather Holden: Can you tell us about the limitations of InSAR and snow cover?

Parwant Ghuman: As I mentioned in the presentation, InSAR tracks targets on the ground, and it needs consistent targets to track. Snow isn’t a consistent target so it can cause some limitations. 3vG monitors a lot of sites around the world that have seasonal snow cover. We monitor many areas in Canada—BC, Alberta, even in northern provinces, such as Nunavut, Northwest Territories—which get a lot of snow. However, you have to rely on snow-free images to a large extent.

You can also use images that are partially covered by snow. But once you have full coverage by snow, even if the ground freezes or not, those are not the type of signals that you’re after. They are not ground displacement signals if you’re in the dead of the winter and the ground is frozen.

What it boils down to is that you have fewer measurements in any given year. You have fewer images to rely upon. In areas like the Northwest Territories, you may only have imaging for five or six months out of the whole year. Because you have fewer images, you have fewer data points. This means you have higher noise in these displacement rates. If you start reducing the number of images, you increase the noise in these displacement maps because you have fewer statistics to rely upon.

So, you have more noise but also gaps in the winter. You would see a displacement—a steady-state of displacement or acceleration happening then there’d be a gap for a few months because it’s snow-covered and then you’re able to start monitoring it again once the snow melts and the ground is snow-free. Our clients who have assets in snowy environments use InSAR regularly, but they just have to deal with a little bit more noise than the clients in the arid areas.

HH: Can you comment on how to address areas with poor InSAR coverage, like if there was an unfavourable wall orientation, as an example. Is there a more suitable processing method to get more out of the data?

PG: Right. I could talk about coverage for a while—how to address poor coverage. The first thing you need is the right satellite. You need the right data. You need the right satellite images, and you need a lot of them. If you try to monitor an area with something like six images per year, you’re not going to get the greatest results. You’re not going to have great coverage and you’ll not get enough early warning.

You want to make sure—this varies based on the client—but you want 15–20 images per year. Many of our clients use more than 30. Some even use 60 images per year, from opposite directions. You also want the right wavelength and the right resolution.

Do you need to penetrate vegetation? Do you need a longer wavelength? If you have small-displacement features that are affecting your assets, then you need a higher resolution. Do you need to zoom in more with a three-metre resolution rather than a 10 or 20-metre resolution?

We assess all these things at the beginning when a user reaches out to us to monitor an asset. We look at the vegetation. We also ask them if they know of any prior history of the ground displacement that exists. A suitable InSAR program is designed based on those requirements.

Now, I should mention something about monitoring the wall that’s not suitably aligned. All of that can be simulated in advance. We can use a digital elevation model, like a LiDAR model, for example, or something even coarser than that, and simulate these satellite passes monitoring this wall or other infrastructure in the area. Through these simulations, we can provide an estimate of where we will get coverage, where we will not get coverage, and where InSAR, maybe lacks sensitivity and where it will be highly sensitive.

Those sorts of things we can assess in advance to set expectations and optimize the observation scenario as much as possible so that the displacement that the user cares about has the maximum chance of being detected and tracked on an ongoing basis.

HH: Pierre, could you please comment on the ShapeArray resolution and the required density of sensors?

Pierre Choquet: ShapeArray comes pre-assembled with 500-millimetre segments and can install into an inclinometer casing or a PVC pipe. ShapeArray can also be installed horizontally for measuring settlement, but let’s go back to when they’re installed vertically for now. ShapeArray precision, which is synonymous with repeatability, is 0.5 millimetres per 30 metres of borehole length.

HH: How can InSAR data be confirmed with ground-based instruments?

PC: Well, ShapeArray is a good example, in the sense that InSAR, as we said, can be decomposed into its horizontal component, mainly east-west. And, as Parwant showed, you also get a sense of the direction of the vector which can be different from exactly East-West. And so, we’re talking about the same thing between InSAR and the ground-based instrument. We’re talking about with ShapeArray, the cumulative horizontal displacement at the collar of the borehole, say of 1.5 millimetres, for example, or any other value which can be compared to the horizontal displacement obtained from InSAR. This means you can directly compare ShapeArray displacement data to the displacement that you have obtained from InSAR.

The advantage of InSAR is that it’s a bit like you have thousands of ShapeArrays that are all over the project site. They give you surface displacements that you can decompose into vertical and horizontal components. This can identify, for example, the slope movement source. For instance, the Cadia Mine failure was the result of a weak, lateritic, weathered formation below the foundation of the dam. With ShapeArray, you’ll know the depth in the ground at which the displacement is happening. Then, you’ll be able to plan with much better remediation measures.

Moreover, ShapeArray or any other in-ground instrument can be automated with data loggers so that you can obtain measurements in near real-time. If movements have been identified with InSAR and those movements are accelerating, you can then read all those ShapeArrays, all those piezometers and so on, every minute if needed. For example, if you were in an emergency situation, you would have that data available.

Elements of the transcript have been edited for clarity and concision.

Speak with an Expert

I’m very happy with the quality of the instrumentation and technical support from RST, as always. They worked with us from the initial stages of the project to ensure that we were fully prepared and equipped to use the RSTAR network for the first time. They delivered everything within the tight project time frame to ensure that there were no delays on site, and the submersible tilt meters looked like new even after over twelve months of being submerged in Thames water!

-Richard Lipscombe, BEng (Hons), Director & Principle Consultant - RL Geotechnical Ltd

Related Posts

Leveraging ShapeArray for wireless automated remote deformation monitoring

Wireless automated remote deformation monitoring is transforming how engineers collect dat...

Wide-area linear infrastructure monitoring with InSAR and Instrumentation: Your questions answered

Terra Insights' Savanna Herman and 3vG's Murray Down presented Wide-area linear infrastruc...

ShapeArray Fundamentals in 2023: Your questions answered

Measurand’s Mitchell Pollock and Terra Insights’ Josh Smith presented ShapeArray™ Fu...